Contact Information

Yantai Yinxing Machinery Group Co., Ltd.

Tel: +86-535-2212923

Whatsapp: +86-15553579872

E-mail: 13863803808@163.com

Drum Malting System

Yinxing is at the forefront of malting innovation with our advanced drum malting systems,designed to cater to the specific needs of modern brewing operations.These systems,which range in capacity from 1 to 10 tons,exemplify our commitment to providing precision-controlled and flexible malting solutions. The drum malting method,a cornerstone of our technology,employs rotating drums to manage the germination process meticulously.This ensures each batch of malt meets the highest quality standards.These systems are not only compact but also remarkably energy-efficient,making them an excellent choice for facilities aiming to enhance production while reducing costs. Key features of Yinxing’s drum malting systems include: Advanced Kilning:Capable of reaching temperatures up to 140°C(284°F),our kilning technology allows for the production of a diverse range of malt types,addressing various brewing requirements. Automated Control System:Equipped with sophisticated monitoring tools,our systems ensure reliable operations and provide accurate data essential for seamless production and quality assurance. Enhanced Airflow System:Our systems feature a uniform air distribution mechanism that optimizes the quality of the malt,ensuring consistency across batches. Versatile Cereal Processing:Our drum malting systems are adept at handling multiple cereal types including barley,wheat,oats,and more,offering great flexibility in malt production. Sealed Stainless Steel Drum Design:The all-stainless steel construction not only maintains optimal saccharification temperatures and humidity for improved enzyme activity but also ensures the malt remains uncontaminated,preserving its quality. Water Spray Feature:Integrated during both germination and roasting phases,this feature allows for precise moisture control,enhancing flavors and maintaining grain integrity. Through these innovative features,Yinxing's drum malting systems stand out in the industry,offering unparalleled efficiency and reliability.By integrating cutting-edge technology with our deep expertise,we ensure that each system is optimized to meet the diverse and evolving needs of our clients,solidifying our position as a leader in malting technology.Whether it's for a small craft brewery or a large-scale malt production facility,Yinxing's solutions are tailored to maximize productivity and ensure superior malt quality.

Category:

Description

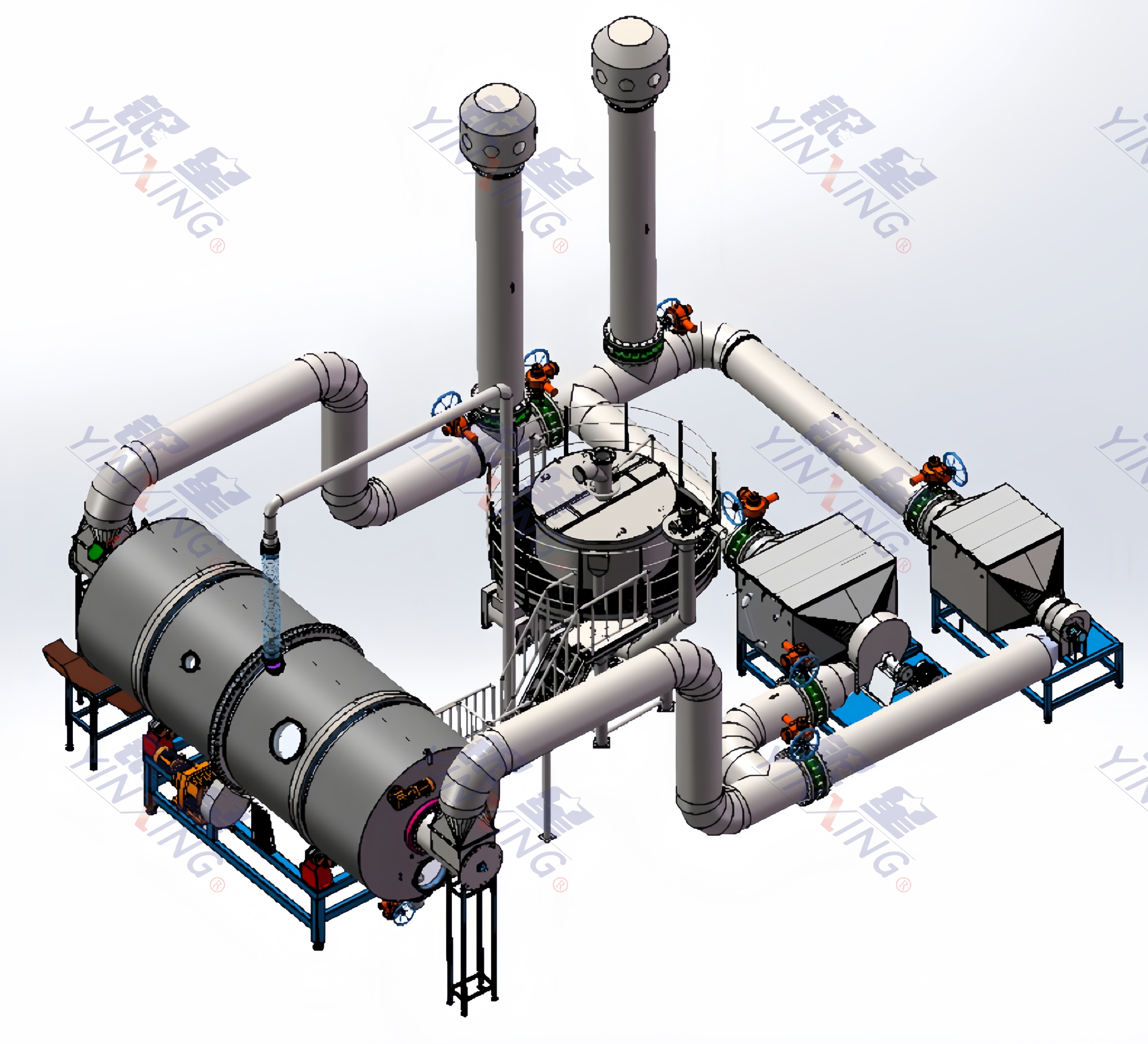

Yinxing is at the forefront of malting innovation with our advanced drum malting systems,designed to cater to the specific needs of modern brewing operations.These systems,which range in capacity from 1 to 10 tons,exemplify our commitment to providing precision-controlled and flexible malting solutions.

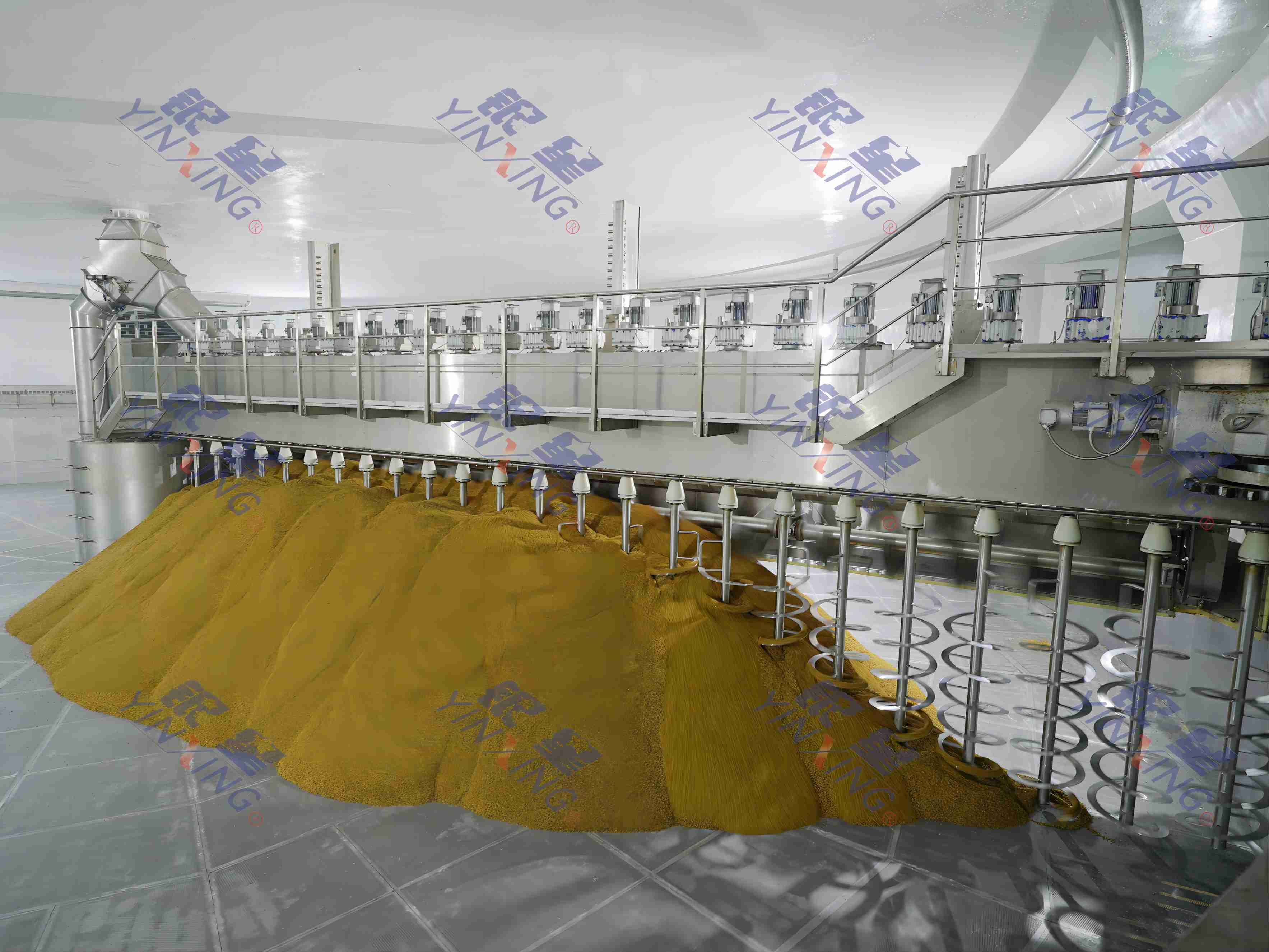

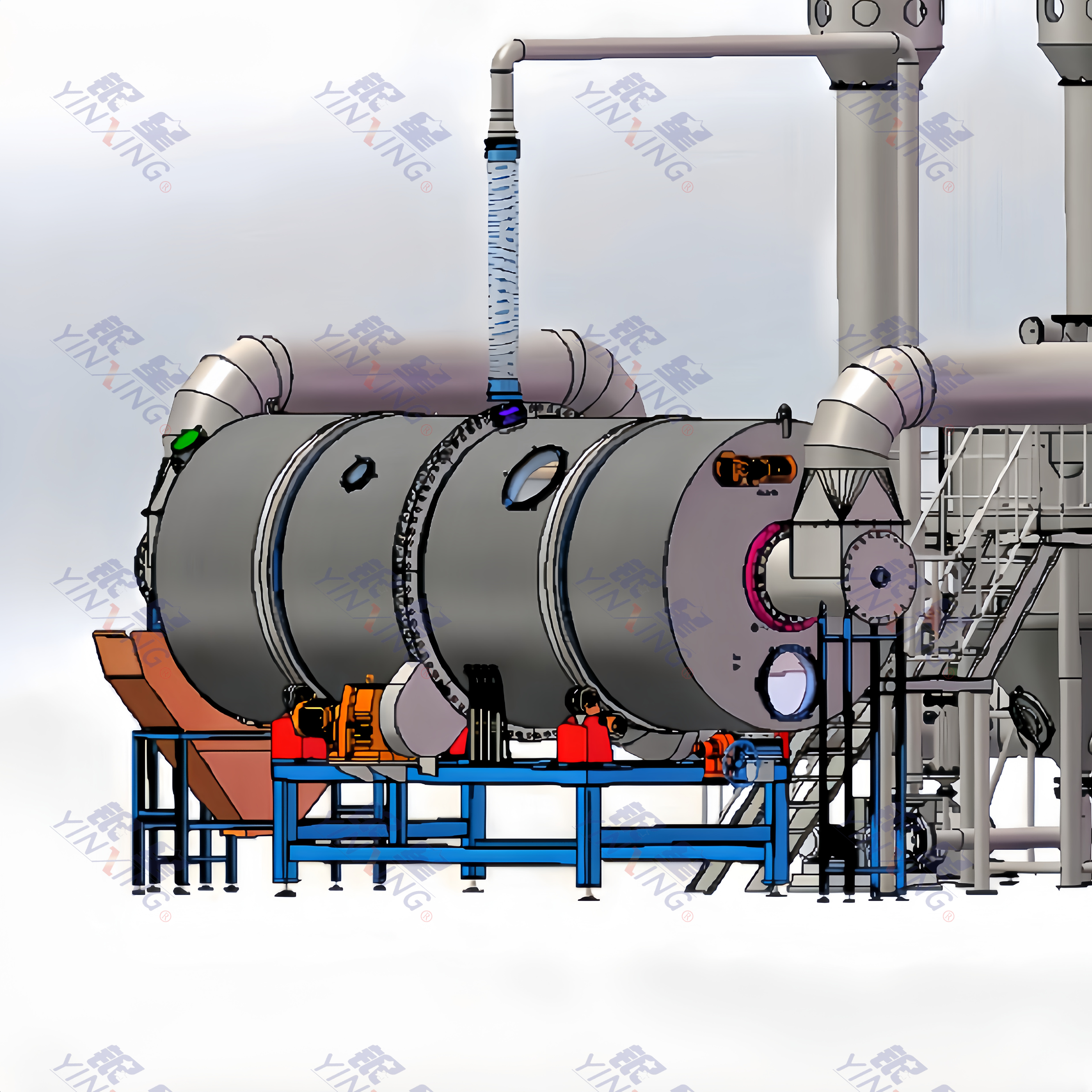

The drum malting method,a cornerstone of our technology,employs rotating drums to manage the germination process meticulously.This ensures each batch of malt meets the highest quality standards.These systems are not only compact but also remarkably energy-efficient,making them an excellent choice for facilities aiming to enhance production while reducing costs.

Key features of Yinxing’s drum malting systems include:

Advanced Kilning:Capable of reaching temperatures up to 140°C(284°F),our kilning technology allows for the production of a diverse range of malt types,addressing various brewing requirements.

Automated Control System:Equipped with sophisticated monitoring tools,our systems ensure reliable operations and provide accurate data essential for seamless production and quality assurance.

Enhanced Airflow System:Our systems feature a uniform air distribution mechanism that optimizes the quality of the malt,ensuring consistency across batches.

Versatile Cereal Processing:Our drum malting systems are adept at handling multiple cereal types including barley,wheat,oats,and more,offering great flexibility in malt production.

Sealed Stainless Steel Drum Design:The all-stainless steel construction not only maintains optimal saccharification temperatures and humidity for improved enzyme activity but also ensures the malt remains uncontaminated,preserving its quality.

Water Spray Feature:Integrated during both germination and roasting phases,this feature allows for precise moisture control,enhancing flavors and maintaining grain integrity.

Through these innovative features,Yinxing's drum malting systems stand out in the industry,offering unparalleled efficiency and reliability.By integrating cutting-edge technology with our deep expertise,we ensure that each system is optimized to meet the diverse and evolving needs of our clients,solidifying our position as a leader in malting technology.Whether it's for a small craft brewery or a large-scale malt production facility,Yinxing's solutions are tailored to maximize productivity and ensure superior malt quality.

Keywords: Drum Malting System

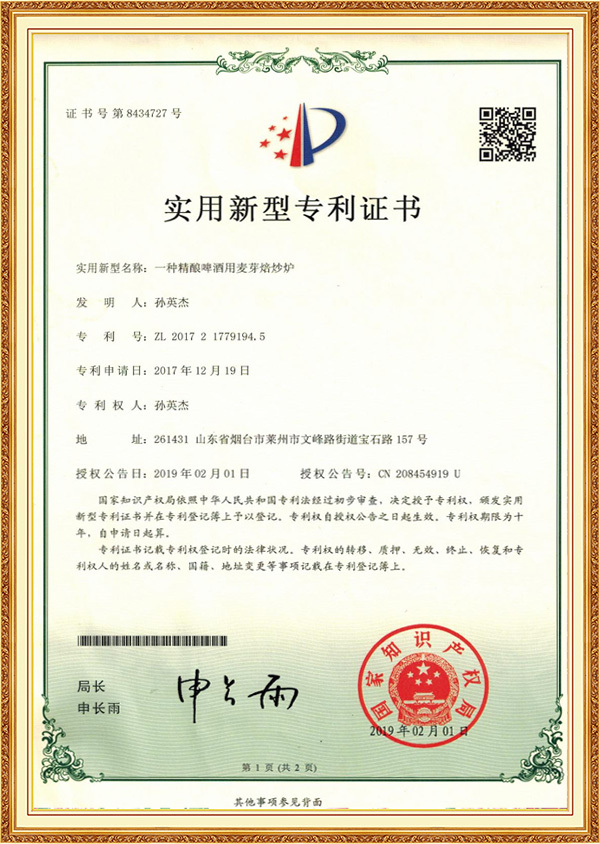

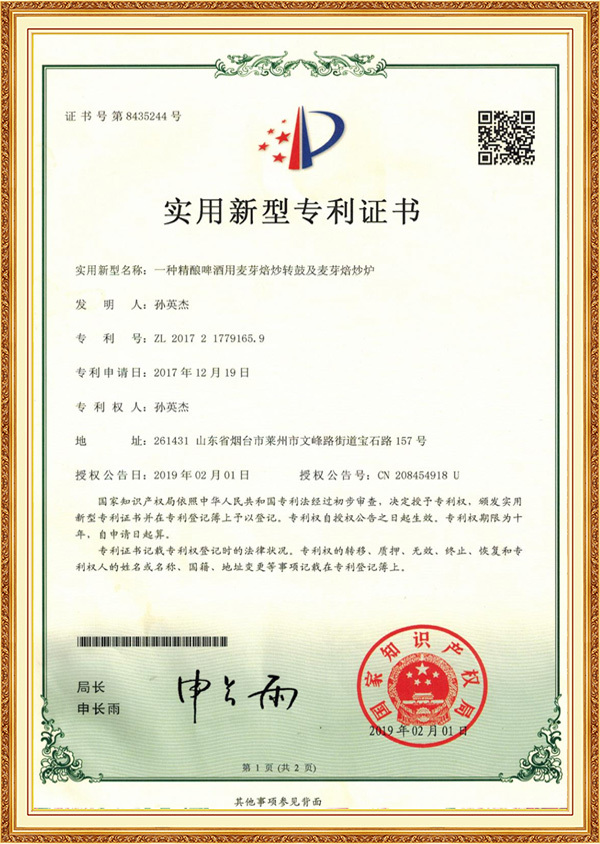

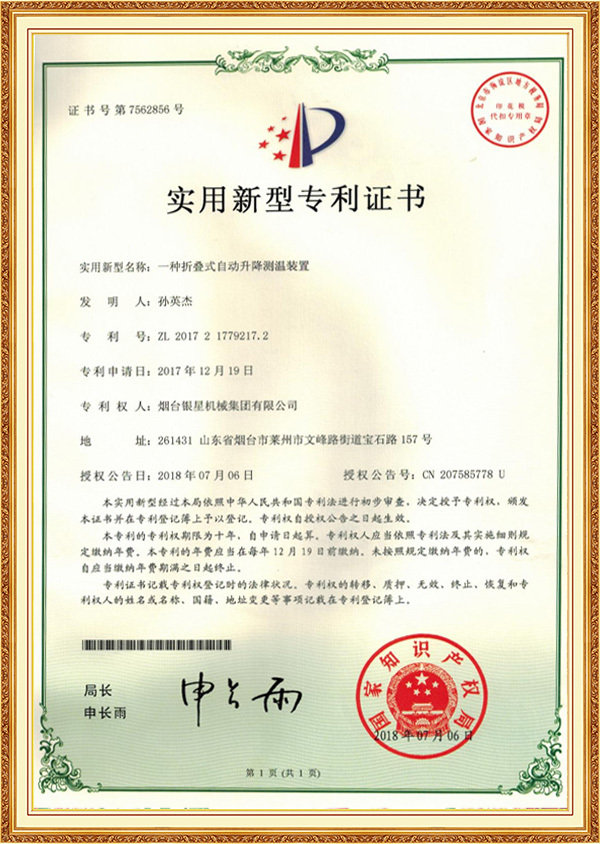

Qualification

Cases

Send Inquiry

NOTE: Please leave your email, our professional person will contact you asap!