Contact Information

Yantai Yinxing Machinery Group Co., Ltd.

Tel: +86-535-2212923

Whatsapp: +86-15553579872

E-mail: 13863803808@163.com

Round Germination Vessel

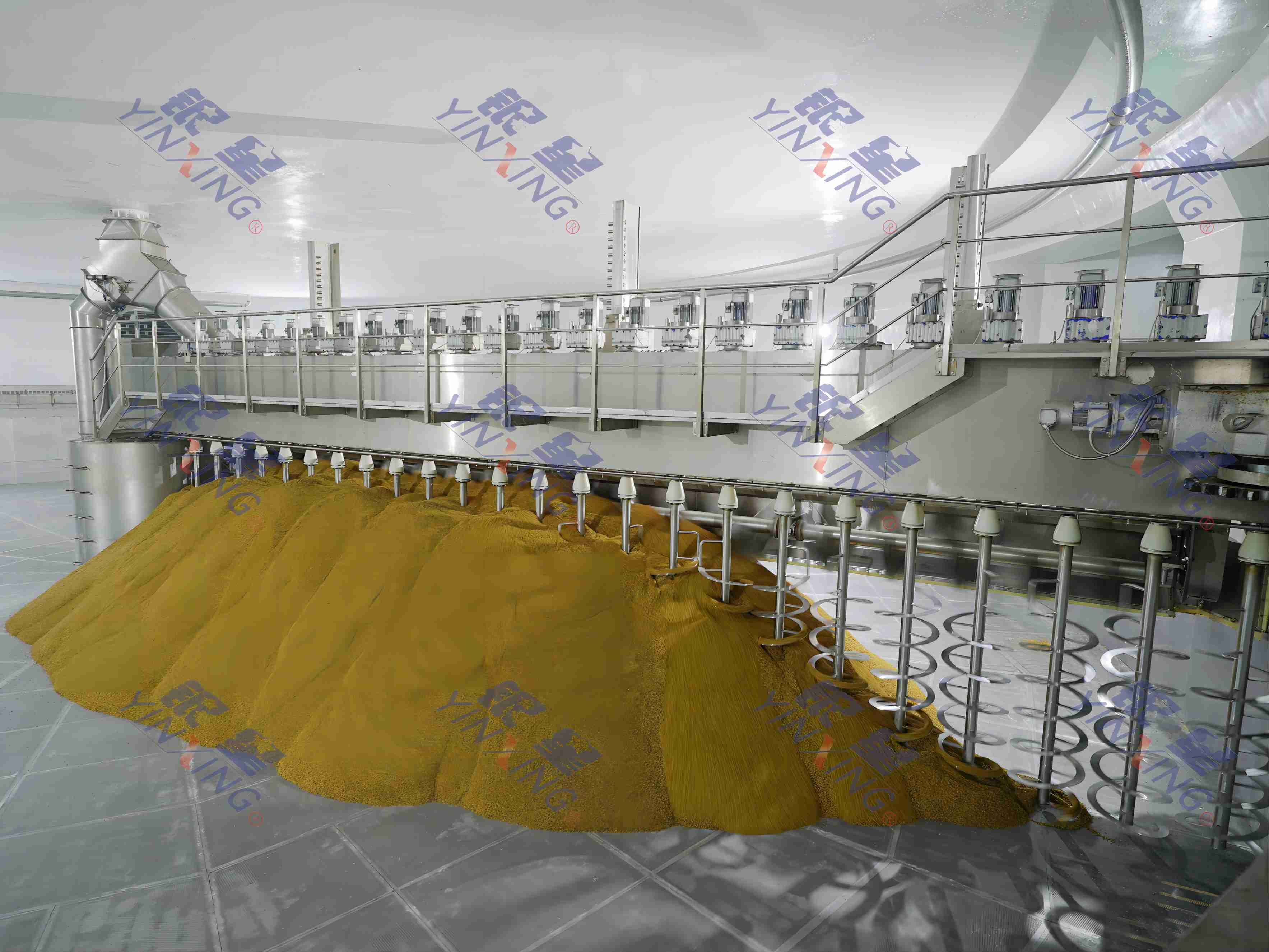

The circular germination system manufactured by Yinxing offers numerous advantages for malt processing. Firstly, its circular design maximizes space utilization, minimizing the footprint of the production facility. This compact layout allows the system to handle large malt volumes while occupying minimal floor space, making it ideal for facilities with limited space. Secondly, the circular layout promotes uniform airflow and temperature distribution within the germination vessel. This uniformity ensures consistent conditions for malt germination, resulting in more even and predictable malt quality. Additionally, the circular motion of the system facilitates thorough mixing and agitation of the malt bed, promoting even moisture distribution and preventing clumping or uneven germination. Moreover, Yinxing's circular germination system is typically equipped with advanced automation controls and monitoring systems. This high level of automation allows for precise regulation of key parameters such as temperature, humidity, and airflow. By minimizing the need for manual intervention, the system ensures stable and repeatable malt production processes. In summary, the circular germination system manufactured by Yinxing provides efficient space utilization, uniform processing conditions, and high levels of automation control. This makes it a reliable solution for malt processors seeking consistent quality and efficient production processes.

Category:

Description

Yinxing Company Round Germination System Overview

At Yinxing Company,our innovative round germination system offers numerous advantages for malt processing,emphasizing efficient space utilization,uniform processing conditions,and advanced automation:

Optimized Space Utilization:

The system's round design maximizes space efficiency by minimizing the facility's footprint.This compact layout accommodates large volumes of malt within a limited floor area,making it ideal for facilities with space constraints.

Uniform Airflow and Temperature Control:

The round layout promotes even airflow and temperature distribution within the germination vessel.This ensures consistent conditions for malt germination,leading to more uniform and predictable malt quality.The system's round motion facilitates thorough mixing and agitation of the malt bed,enhancing moisture distribution and preventing uneven germination.

Advanced Automation and Monitoring:

Equipped with sophisticated automation controls and monitoring systems,our round germination system allows for precise regulation of temperature,humidity,and airflow.This high level of automation reduces the need for manual intervention,ensuring stable and repeatable production processes.

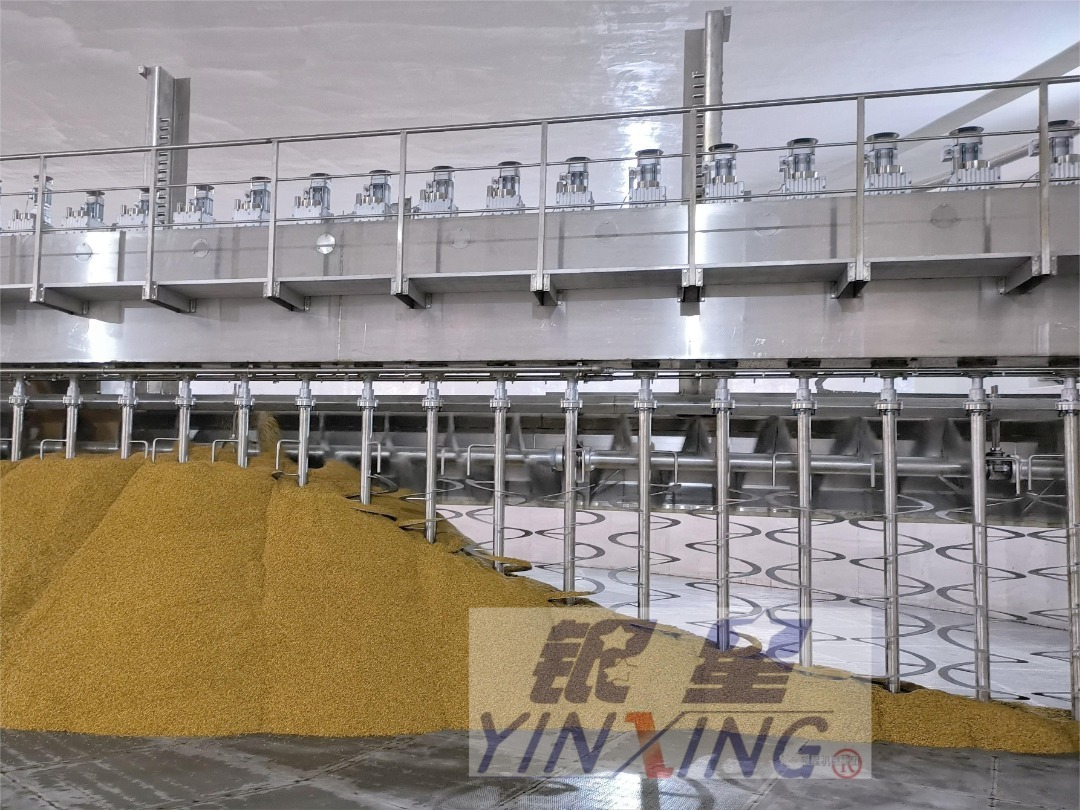

Innovative Malt Flipping and Stirring Device:

The system includes a tank-type girder and 21 vertical malt turning auger shafts,engineered for efficient grain turning.The turning augers are designed to lift the grain gently,ensuring flawless mixing without damaging the kernels.The shafts are easily maintainable,with components that can be replaced as needed to minimize downtime.

Integrated Malt Handling and Hygiene:

Product loading and unloading are streamlined with our germination boxes,which feature a combined turning,loading,and unloading screw for homogeneous mixing and aeration.The system includes powerful aeration fans and a high-performance ventilation system to control environmental conditions.Additionally,a high-pressure cleaning system maintains the highest levels of hygiene and sanitation,automatically cleaning both above and beneath the germination floor.

Flexible Installation Options:

The round germination system is versatile,available for installation in both tower and flat plant configurations,accommodating different plant layouts and production needs.

Keywords: Round Germination Vessel

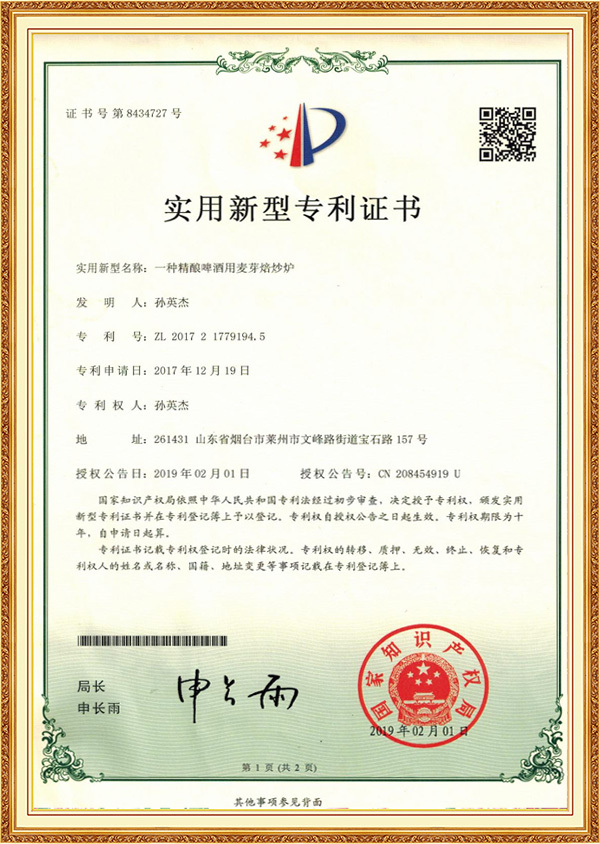

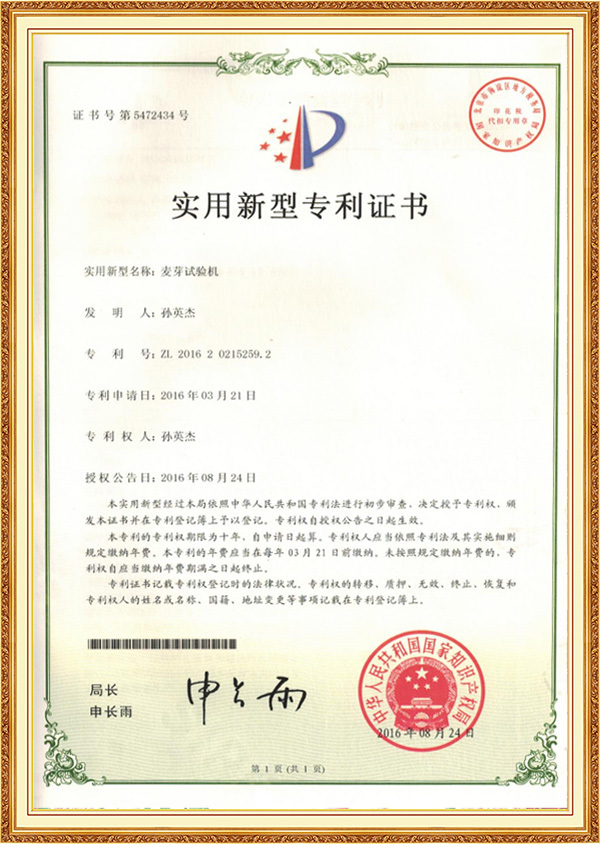

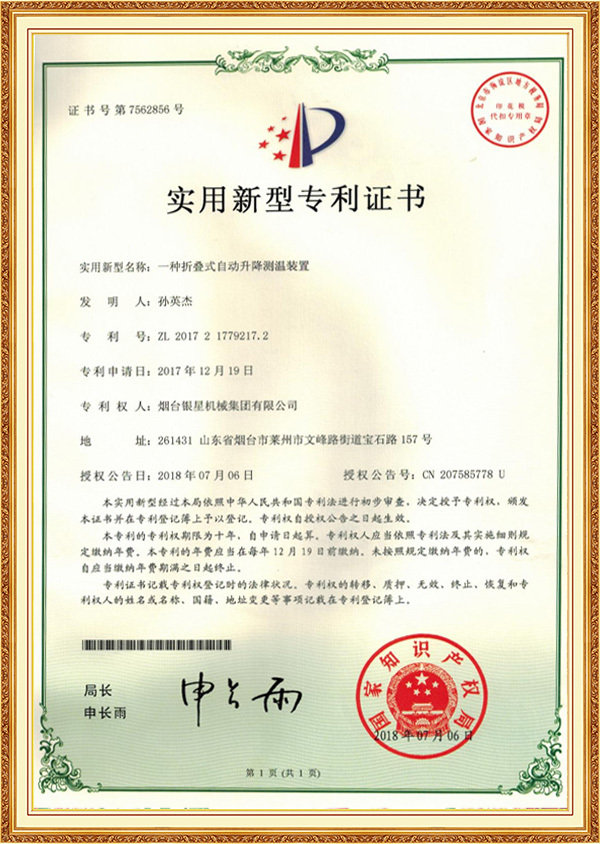

Qualification

Cases

Send Inquiry

NOTE: Please leave your email, our professional person will contact you asap!