Contact Information

Yantai Yinxing Machinery Group Co., Ltd.

Tel: +86-535-2212923

Whatsapp: +86-15553579872

E-mail: 13863803808@163.com

Description

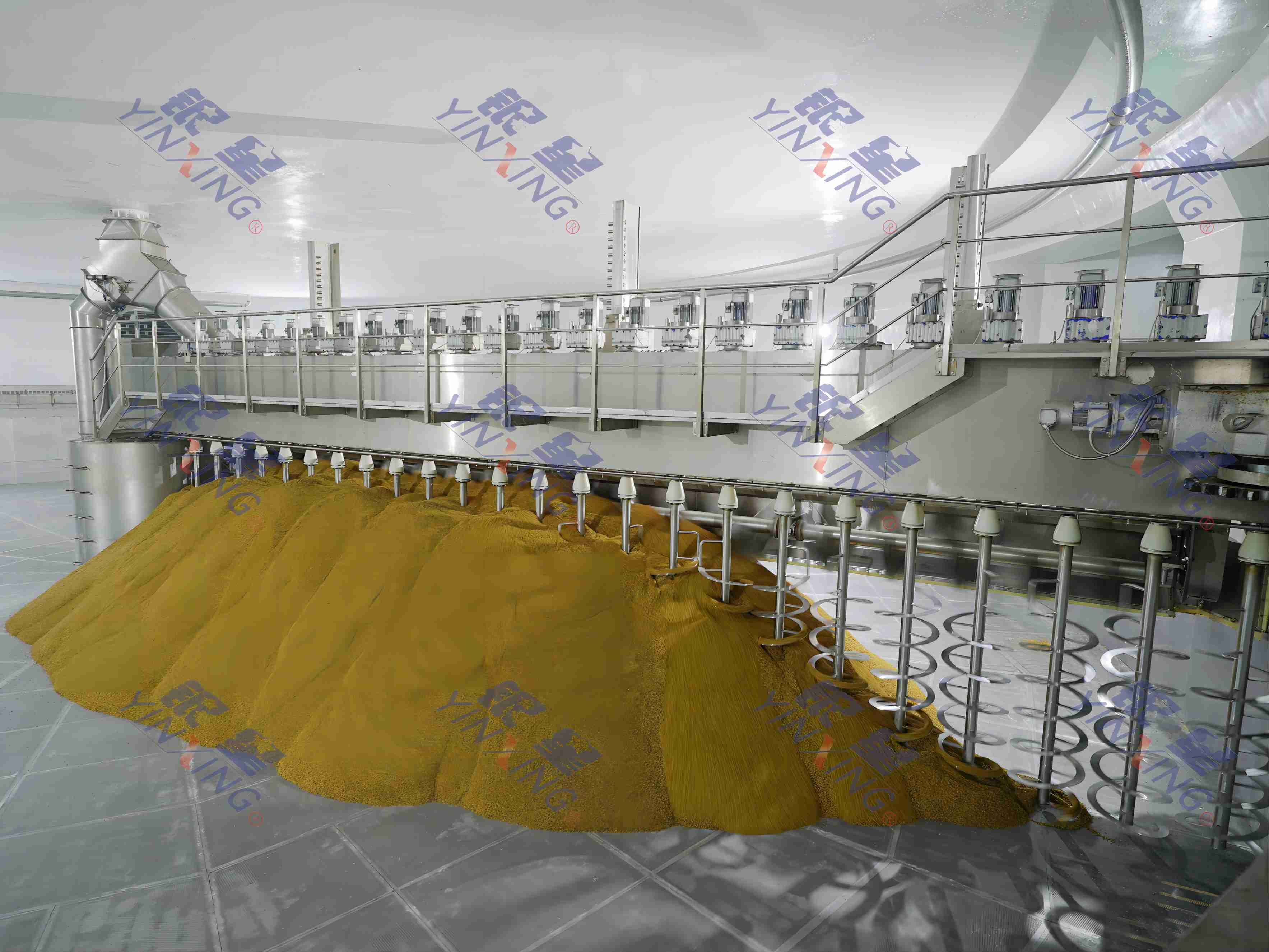

Rotary Vibrating Screen for Malt is a key piece of equipment used in malt production and processing, primarily for screening and grading malt particles to ensure the required particle size and purity for subsequent processes. This equipment is widely used in the malt, brewing, and food processing industries.

Working Principle

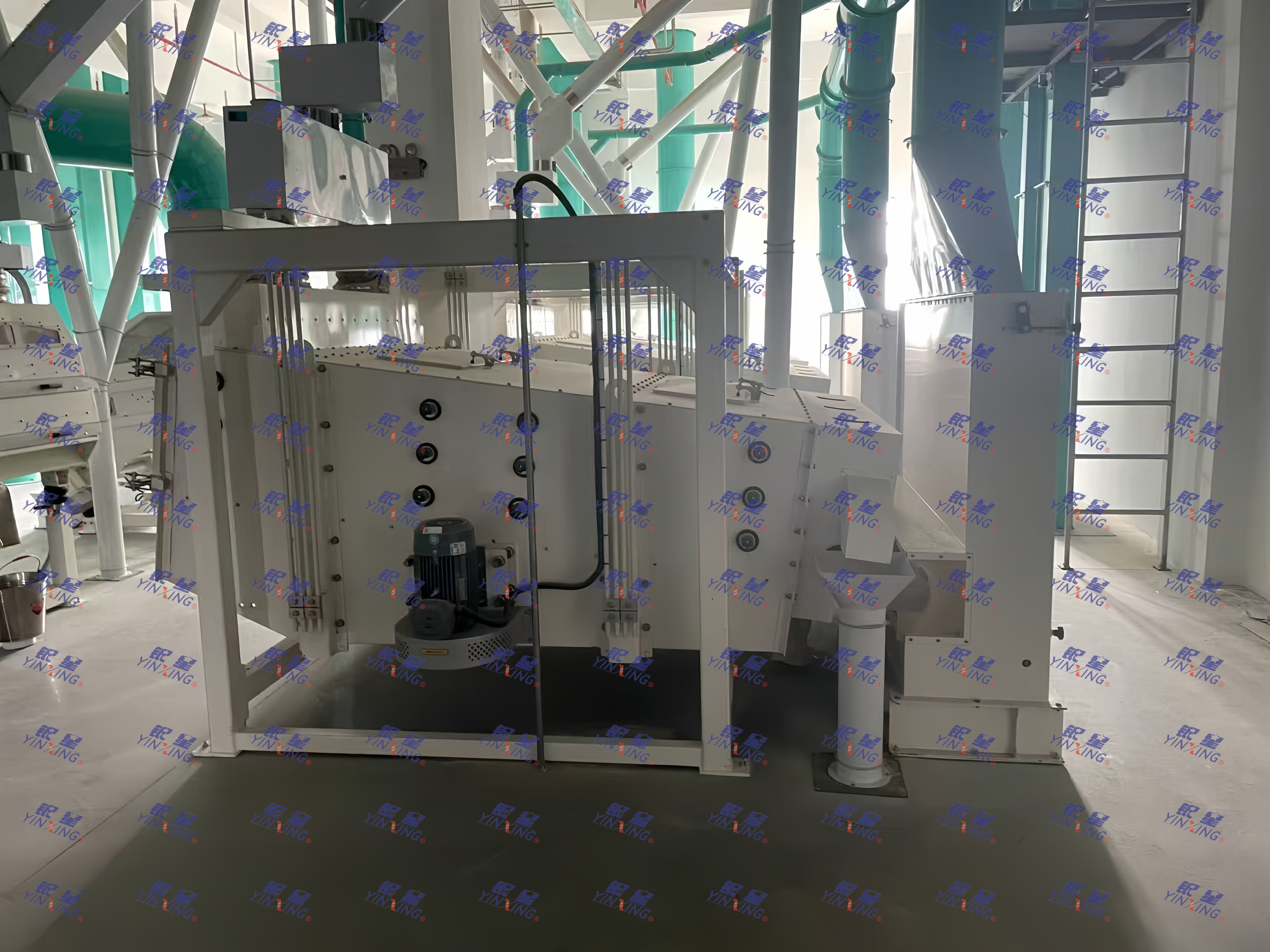

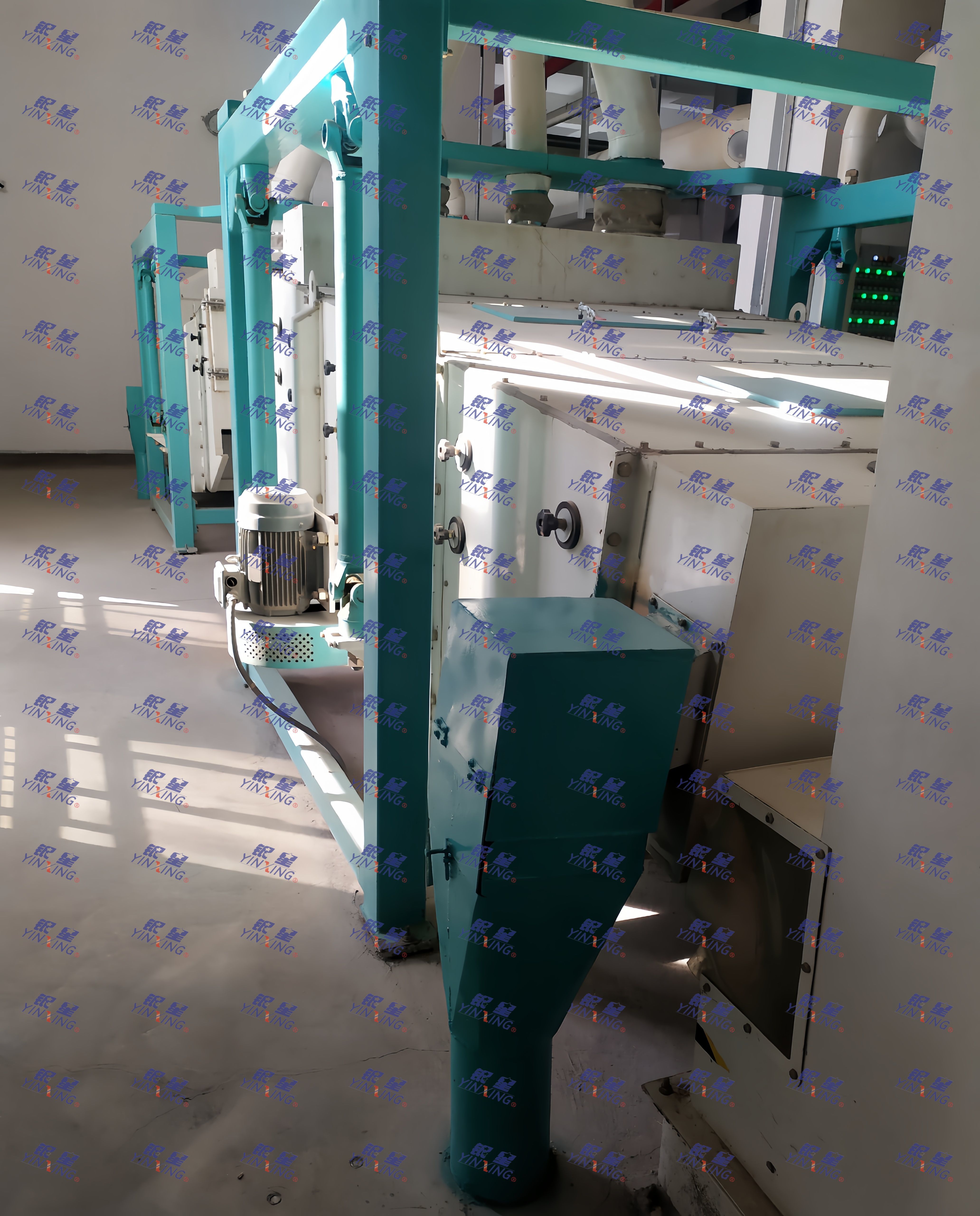

The Rotary Vibrating Screen for Malt utilizes one or more vibrating motors to generate high-frequency vibrations that drive the screen. The vibrations cause the malt to evenly distribute across the screen and pass through the mesh. Different particle sizes are separated by the screen, with smaller particles falling to the lower layers and larger particles remaining on top, thereby achieving classification.

Features

High-Efficiency Screening: The advanced vibration technology allows for efficient screening and precise grading, ensuring consistent malt quality.

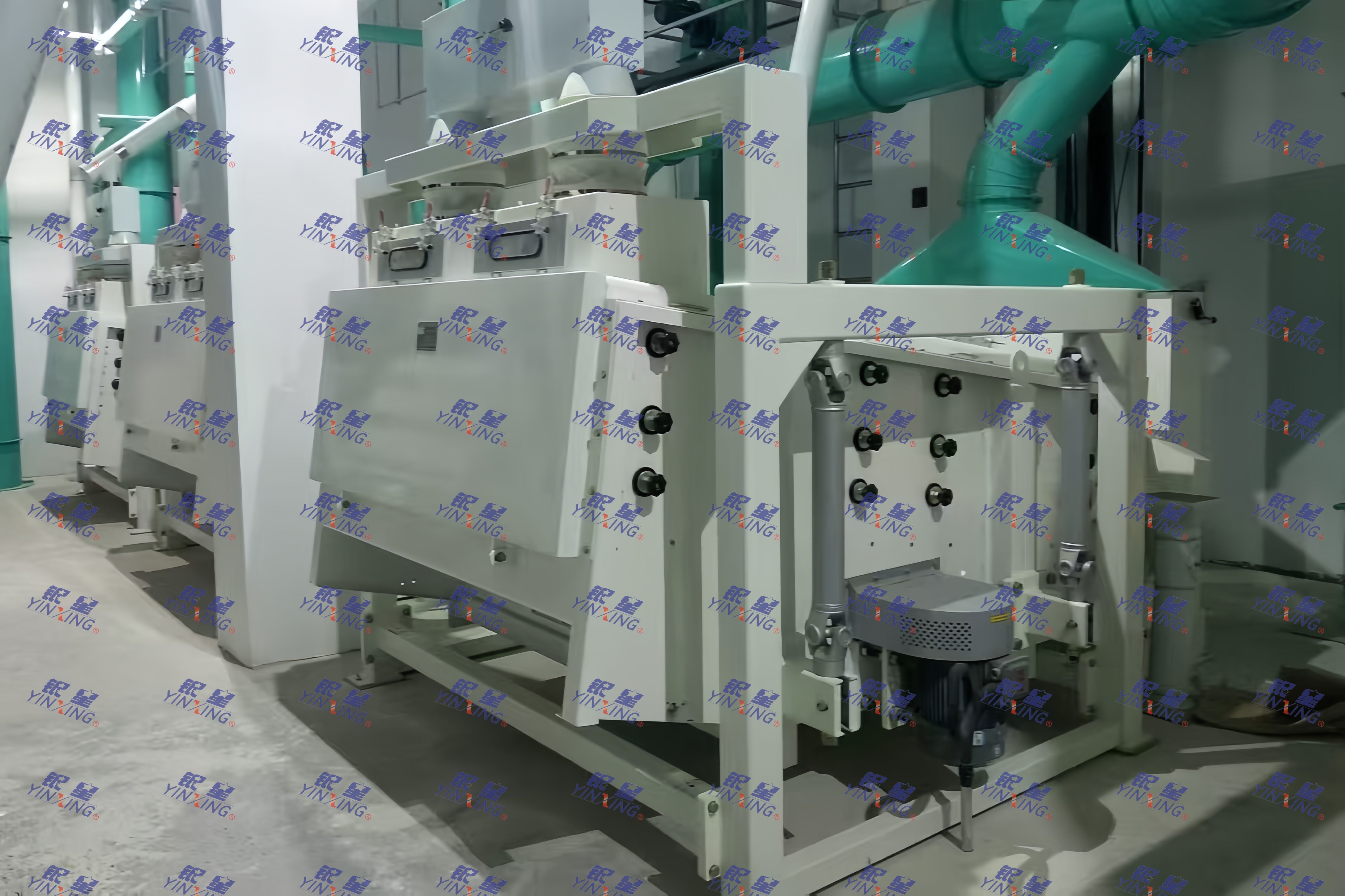

Multi-Layer Screens: The equipment supports the configuration of multiple screen layers, allowing users to achieve various grading effects according to their needs.

Compact Structure: The equipment is compact, occupying a small footprint, making it suitable for malt processing plants of different sizes. It can be easily integrated into existing production lines.

Low Energy Consumption: The vibrating motors consume minimal power, making the operation economical, while also ensuring durability and stability.

Easy Maintenance: The simple structure of the equipment allows for easy assembly and disassembly, facilitating daily maintenance and cleaning, reducing downtime, and enhancing production efficiency.

Applications

- Malt Grading: During malt production, the rotary vibrating screen is used to remove unmalted grains or impurities, ensuring the purity and quality of the finished malt.

- Brewing: Ensures uniform malt particle size, stabilizing the brewing process and the final flavor of the beer.

- Food Processing: Besides malt, the equipment can also be used for screening and grading other grains and cereals, offering wide application prospects.

Wide Range of Models

The Rotary Vibrating Screen for Malt comes in various models to meet different production scales and process requirements. We calculate and recommend the most suitable model based on the customer’s production capacity. Different models vary in screening capacity, number of layers, mesh size, vibration frequency, and more to suit various production environments and yield requirements.

Model Selection Guide

- Small-scale plants: Suitable for models with smaller processing capacities, such as single or double-layer screens, to meet small batch production needs.

- Medium-sized plants: Can opt for medium-capacity equipment with more layers and larger screen areas, suitable for stable medium-scale production.

- Large-scale plants: It is recommended to use models with higher processing capacity, supporting multi-layer screens and higher screening efficiency to meet large-scale production needs.

We are committed to providing customized solutions for our customers. By precisely analyzing production capacity, we ensure that every customer receives the best-configured Rotary Vibrating Screen for Malt, optimizing production processes and enhancing product quality.

Keywords: Rotary Vibrating Screen

Qualification

Cases

Send Inquiry

NOTE: Please leave your email, our professional person will contact you asap!