PRODUCTS

Contact Information

Yantai Yinxing Machinery Group Co., Ltd.

Tel: +86-535-2212923

Whatsapp: +86-15553579872

E-mail: 13863803808@163.com

Germination Solutions

Our germination systems are characterized by fast and homogenous product loading and unloading.Accurate and uniform aeration results in the highest quality malt.With our patented vessel system,capable of handling up to 600 tons per batch,we help you save time and money during the construction of your plant.Our system holds the record for the largest batch capacity in China.

By integrating our advanced germination solutions into your malting process,you can achieve faster processing times,improved malt quality,and significant cost savings.Our expertise and innovative technology ensure that your germination stage is efficient,effective,and tailored to meet your specific needs.

Germination Solutions

At Yinxing Company,we offer two advanced germination solutions to meet the diverse needs of malt processing facilities:the Rectangular Germination Vessel and the Round Germination System.Each system has unique advantages and considerations,ensuring you can select the best option for your specific requirements.

Rectangular Germination Vessel:

The Rectangular Germination Vessel is designed for economical manufacturing and installation.Its simplicity and standardized construction reduce initial investment,making it an affordable option for malt processing facilities,particularly those with budget constraints.This vessel promotes efficient airflow and temperature distribution within the germination chamber,ensuring consistent conditions for malt germination and leading to even and predictable malt quality.Equipped with sophisticated automation controls and monitoring systems,this vessel allows for precise regulation of temperature,humidity,and airflow,minimizing the need for manual intervention and ensuring stable production processes.The design includes powerful aeration fans and a high-performance ventilation system to control environmental conditions.A high-pressure cleaning system maintains high levels of hygiene,automatically cleaning both above and beneath the germination floor.The Rectangular Germination Vessel is suitable for flat plant configurations,offering flexibility for various facility layouts.

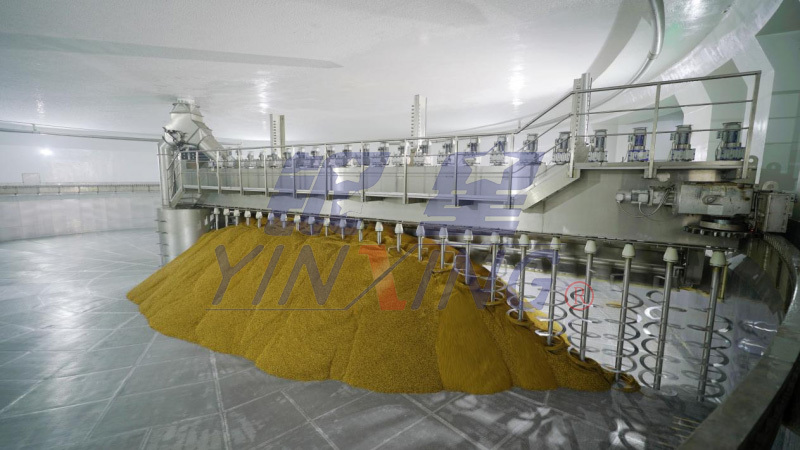

Round Germination System:

The Round Germination System maximizes space efficiency by minimizing the facility's footprint.This compact layout accommodates large volumes of malt within a limited floor area,ideal for facilities with space constraints.The round design promotes even airflow and temperature distribution within the vessel,ensuring consistent conditions for malt germination.This results in more uniform and predictable malt quality.Similar to the rectangular system,the round system features sophisticated automation controls and monitoring systems for precise regulation of temperature,humidity,and airflow,reducing the need for manual intervention.This system includes advanced malt turning mechanisms that gently lift the grain,ensuring thorough mixing without damaging the kernels.The components are easily maintainable to minimize downtime.Product loading and unloading are streamlined with powerful aeration fans and a high-performance ventilation system,maintaining optimal environmental conditions.The high-pressure cleaning system ensures high levels of hygiene and sanitation.The Round Germination System is versatile,available for installation in both tower and flat plant configurations,accommodating various plant layouts and production needs.

By choosing either the Rectangular or Round Germination System,you can enhance the efficiency and quality of your malting process.Each system offers distinct advantages,allowing you to select the one that best fits your facility's needs.With Yinxing Company's expertise and innovative technology,you can trust that your germination stage will be efficient,effective,and tailored to your specific requirements.